Detailing out an efficient design-build workflow

From commercial to residential builds, Scott Miller from Remington Development Corporation uses the SketchUp suite of tools to perfect the conceptual design process. Learn how this SketchUp pro uses his skills to help move design-build projects forward for the large, Canadian-based real estate development company.

Give us a little bit of background on your role(s) over the past several years.

I am an architectural designer and have been in the industry for over two decades. I’ve worked for several real estate development companies, earlier as an intern architect with Dialog and IBI Group, and now with Remington Development Corporation, where I’ve designed over 100 buildings. At IBI Group, I was responsible for concept design and project management, working on 20 to 30 projects that facilitated concept design all the way to design documentation and construction administration. At Remington, I work with a team of brilliant individuals and focus on the conceptual design phase, investigating development opportunities on various land types, or preparing proposals for leasing opportunities.

In my current role, timing is critical, so I rely on several different tools in and outside of the SketchUp suite to execute accurate and timely proposals. The software contingent I use daily includes SketchUp Pro, Sefaira, V-Ray, and Adobe Photoshop & Illustrator.

How long have you been using SketchUp, and why do you choose to continue using it ?

I’ve been using SketchUp since 2008! I started out using SketchUp’s basic tools to get design ideas out quickly. Over the years, I advanced my skills and learned how to use SketchUp for building design, site plans, and master plans. Having mastered my workflow and various shortcuts, I significantly increased my efficiency.

“SketchUp is a very intuitive software that helps me expand on ideas, which is why I continue to use it. It enables me to offer our internal group and clients multiple design options quickly. I also use it to help our construction group understand the costs associated with the proposed designs while ensuring we meet local regulatory building codes.”

What does your typical workflow look like?

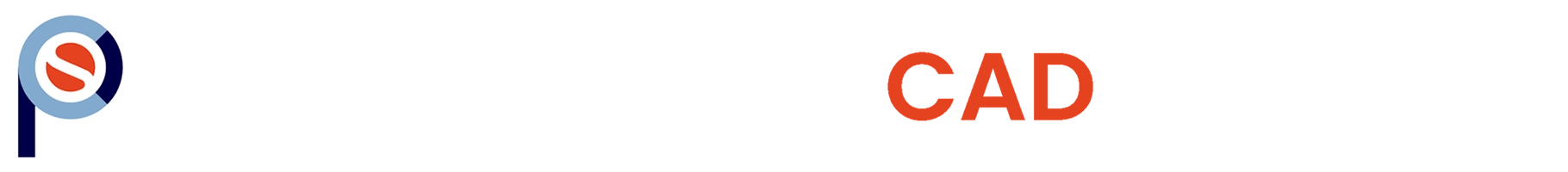

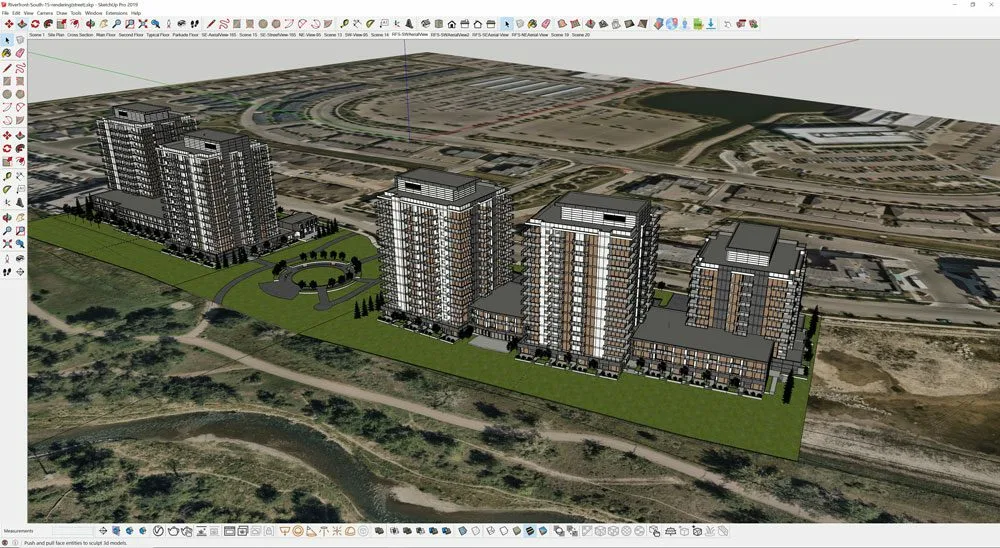

Over time I’ve honed my workflow and, in turn, have become a faster modeler. Typically, my design-build workflow starts with an idea or concept. This concept is then tested relative to a site and is developed into floor plans, a massing model and then a model that’s suitable for rendering. Depending on the project, I may start modeling with a typical floor and transition to a main floor base with parking below, for say a residential project. For an office building a structural grid and parking lot may drive the modeling process. But for all projects a concept is foremost and SketchUp helps me to illustrate that idea quickly.

Detailing my overall workflow process, I mainly create massing models, which are not too intricate but are still based on real-life building systems. From there, I import a site map and 3D Warehouse models which saves some time building out the surrounding context, such as roads, foliage, and furniture. The Placemaker extension is very helpful for populating the models with the site context. And all these steps help ground my model into its real-life surroundings. For more complex sites, contours from a survey are used to develop a terrain model that can inform the initial design process.

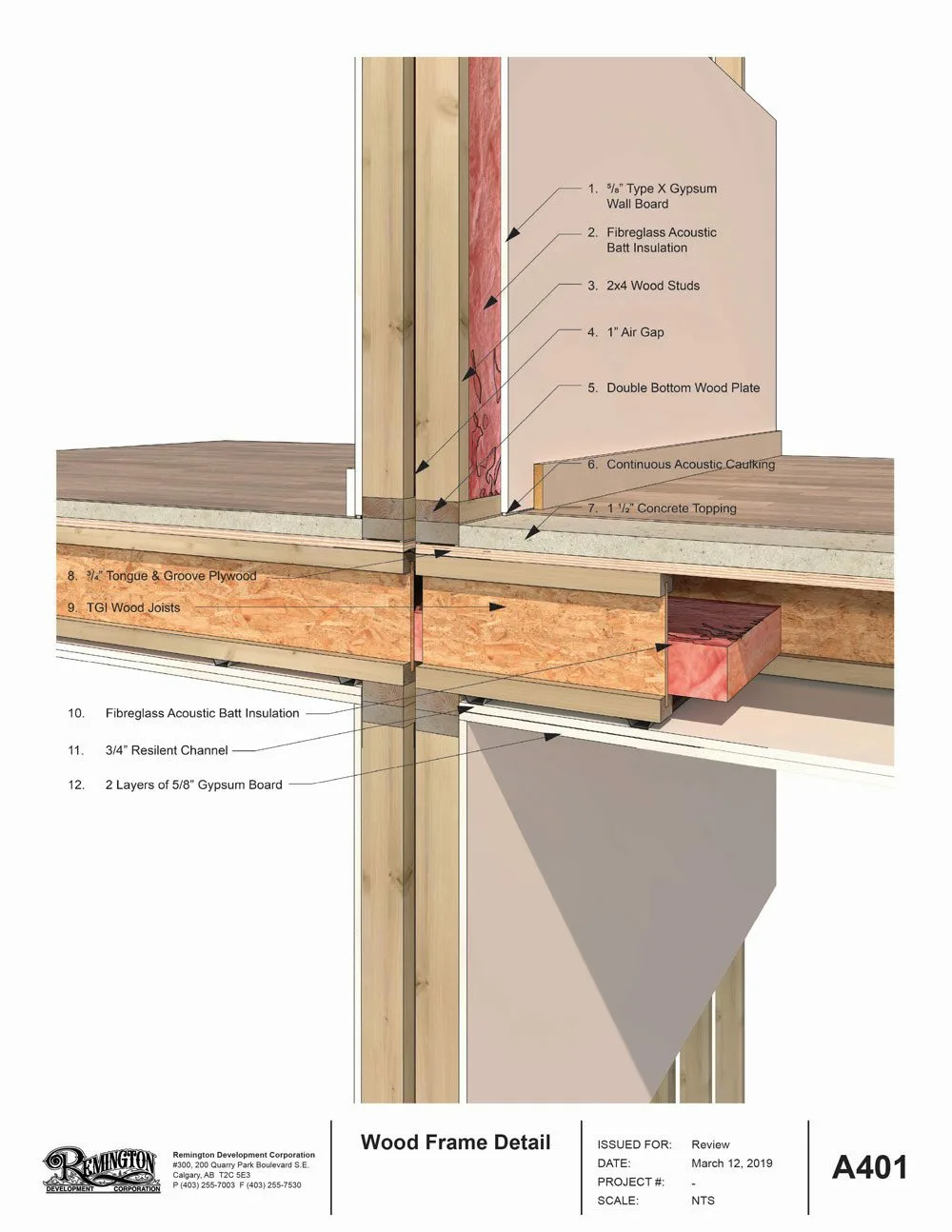

Once the 3D model is built, a structural grid is implemented, usually with a blindside call to the engineers at RJC, and details are added to the project based on real world-building requirements. This helps me determine the cost of the project. Area take-offs and volume of materials required, such as concrete for the building’s foundations or areas of vision glass, are used to develop construction budgets. On top of that, I use SketchUp to review the location and dimensions for doors, stairs, and windows to ensure the buildings I am designing are up to building code standards.

Another benefit of using SketchUp is the ability to use Sefaira. During the conceptual stage, I assign values to walls, windows, and the foundation to review compliance with our national energy codes. Although these are high-level numbers, they give me – and our group or our client – a rough idea of the energy consumption based on the location’s climate that can affect the materials proposed. The analysis provides a basis to start discussions with, in this case, our sustainability engineers. We are able to identify where we may have issues with energy loss through the building envelope, what our equipment/lighting power requirement limits are, or minimum values for the construction assemblies and glazing systems. Once this building performance analysis is complete, it is sent to our mechanical engineers.

Once the design develops, I render it all in V-Ray, which, thanks to a four GPU Boxx computer, can be done in minutes. My team pulls these renders into proposals or presentations for the client’s review. For people that aren’t used to CAD or 3D modeling, the rendering really helps them visualise how a building will look when it’s complete, which is ideal for getting approvals or conveying design intent.

“Most projects are time-constrained so with SketchUp, V-Ray and Sefaira I can do all of this fairly quickly and offer up different design options in real time. SketchUp also enables me to do details in 3D that can assist in constructing the building or relaying construction assembly to our client.”

Diving a little deeper, has Sefaira helped save you money, or helped you choose one material or shading type over the other?

Generally, compliance with these energy codes costs us money, but the benefit of Sefaira is that we can see which systems need attention so we can place our efforts in the proper areas. In terms of materials, Sefaira helps us select materials and justify the use of a particular system. For example, Sefaira showcases the benefits of using a good glazing coating and how it can contribute to a more energy-efficient building, which can justify the added expense compared to upgrading the mechanical system. Similarly, when we look at wall assemblies we can see directly how a well-insulated wall, roof, or floor assembly can contribute to building energy efficiencies.

How do you collaborate with your entire team?

Each member of our team has a different role in a design-build project. Although I am responsible for the conceptual design phase of these buildings, we also have team members that do not have a working knowledge of SketchUp or CAD who help pull together the presentations based on my work in SketchUp and V-Ray. Additionally, we have a team of architects and engineers that help us interpret our needs for structure, mechanical, electrical and even energy analysis that we started in Sefaira, which can impact the process and lead to further design iterations. With more recent energy codes, energy consumption will need to be considered at the concept stage. We all work together, in different programs, with the initial design starting from SketchUp. CAD files are exported from SketchUp or the SketchUp file is cleaned up so that it can be imported into other 3D software that our architects can use to generate development & building permit drawings.